Dr. Ake Almgren, International Battery

With today’s focus on designing more environmentally friendly products and taking advantage of the latest energy storage technologies, it behooves designers to look at the process by which batteries are manufactured. It would not make sense if we are actually putting more toxins and pollutants in our environment in the quest to be green.

Traditionally, Li-Ion electrodes are made using a slurry-based process, which uses large amounts of organic solvents to homogeneously mix the components of active materials. The solvent predominantly used in the Li-Ion industry is N–Methylpyrrolidone (NMP). For the solvent-based process extensive and expensive recovery equipment, hoods and other precautions are necessary.

A significant advancement has been made with water-based processing aimed at reducing battery costs and protecting the environment at the same time; giving designers a greener choice when specifying Li-Ion batteries.

At International Battery, the focus is on manufacturing Li-Ion cells using a water-soluble binder (WSB) based process for both the cathode and anode. By eliminating the solvent from the manufacturing process, the capital expenditure cost and the manufacturing cost can be reduced considerably. The WSB process uses water as a medium to dissolve and disperse the binders and the electrode materials respectively.

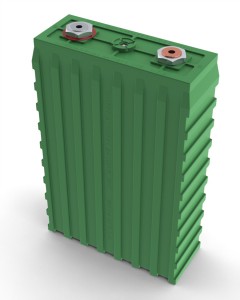

Another important advancement are the large format prismatic battery cells. Different from their smaller cousins used in flashlights and iPods, large format Li-Ion prismatic batteries (see Figure 1) provide more optimal building blocks to deliver higher amounts of energy and scale up as energy demands increase.

Designing a battery system with large format prismatic cells mean less connections and wiring, which reduces cost and also helps the thermal management and maintaining a high energy density of the system. With large format prismatic cells each individual cell can be monitored. It enables the battery management system (BMS) to more precisely know the state of the battery and provide active balancing of the cells. It results in a more efficient utilization of the stored energy in the system.

Large format Li-Ion cells are now being manufactured and deployed using the water-based manufacturing process. Applications currently using or testing large format cells include military vehicles on silent watch, diurnal (renewable) energy storage, backup power for telecommunications as well as hybrid vehicles and distributed energy storage for utilities.

One example of the latter is Community Energy Storage (CES). Coined by utility, American Electric Power, CES is part of the utility’s Ohio gridSMART demonstration project. As part of this first-of-its-kind project, AEP and system integrator, S&C will test large format Li-Ion batteries.

Another interesting project utilizing energy storage has been deployed in Maui, Hawaii. With electricity rates the highest in the country, the Maui Economic Development Board wanted to assess the effectiveness of storing solar energy using efficient battery technology. The renewable energy system is comprised of sixty 224-watt photovoltaic panels, a bi-directional three-phase inverter system and a state-of-the-art charge-controller network provided by HNU Energy in Maui. A 48 V, 16.4 kWh Li-Ion based energy storage system was integrated, complete with battery management and controls, to store the energy generated from the solar array.

The energy storage system includes four battery modules, totaling 32 160 Ah lithium iron phosphate (LFP) cells and a battery management system (BMS) that is integrated into a standard 19-inch portable rack mount chassis and enclosure (see Figure 2). As with the CES project, large-format Li-Ion batteries were chosen because of their proven high-energy density, robust thermal and cycling performance as well as easy system expandability.

The Future

As exciting applications such as electric vehicles and the smart grid drive innovations and transform their respective industries, the role and significance of Li-Ion batteries continues to increase.

From an economic and environmentally-sustainable perspective, the future looks very bright for energy storage incorporating Li-Ion cells. At International Battery we believe, based on performance results and cost analyses, that water-based processing and new large format form factors will help expand Li-Ion adoption in many key industries.

Contact International Battery at www.internationalbattery.com.

This article was printed in the May/June 2010 issue of Battery Power magazine.