Jeffrey Ortega, Ph.D., Director of Research, ZPower

July 7, 2017 | According to the Environmental Protection Agency, Americans buy approximately three billion dry-cell batteries each year to power common household devices, including radios, toys, phones and computers. This volume creates nearly 180,000 tons of battery waste that is either recycled or ends up in landfills, where it can leach toxic chemicals into the ground and water supply. And while this number is staggering in and of itself, we live in a battery-powered world, and our need is only growing. Globally, battery demand is slated to rise 7.7 percent by 2019. Much of that demand will be for the standard lineup of battery-powered products, but there is also a new market segment hungry for battery powerwearables. The pros and cons of this trend are numerous. While increased demand is great for battery manufacturers, product design is posing new problems for the recycling industry. As technology continues to require more power from smaller batteries, issues, such as recyclability, waste volume and safety, are requiring more innovation and options from both battery engineering and chemistry.

Wearables and the Issue of Recycling

The wearables market is slated to grow threefold in the coming years, with 245 million devices sold by 2019. And while innovation is propelling new devices to market at a rapid clip, safety and manufacturing costs are creating an end-of-life product recycling problem that can have huge negative implications. Namely, the batteries in wearable devices are being increasingly glued and/or sealed into their products, making disassembly expensive, if not impossible. According to a recent article by Call2Recycle CEO and President Carl Smith, this trend in product design in both wearables and other common electronics helps keep manufacturing costs down and cuts down on product weight. Sealed-in batteries also provide an added layer of battery safety for the consumer, but, as Smith notes, because disassembly is so cost prohibitive, more and more whole products designed in this fashion are ending up in landfills. The results are fewer opportunities for recycling all of the various components in use and greater opportunities for battery waste to act as a landfill contaminant.

There is no doubt that wearable technology is here to stay. From watches that track everything from the minutes in a day to the location, step count and heart rate of their wearers to rings that double as emergency assistance devices, the wearables tech race is on with no sign of stopping. To add to this trend, another tech innovation is on the horizon that will likely make this recycling problem even worse. According to Grand View Research, the global earphone and headphone market was valued at $8.7 billion in 2015. By 2023, Credence Research predicts that the number will reach $18.6 billion thanks to a compound annual growth rate of 6.2 percent. Wireless headphone technology is driving this explosive growth, and where there are no wires, there are batteries lots and lots of batteries. What becomes of these countless products and the batteries that power them when they cease to be useful is largely dependent on whether or not they can be easily and profitably disassembled.

Sealed-In for Safety

As noted, there are a number of reasons why tech designers are choosing to seal batteries into their products. But while design shape and manufacturing costs can, and likely will, be improved upon as the technology becomes more sophisticated, when it comes to toxic and/or flammable batteries, such as lithium-ion batteries, which are the current battery of choice for many of these devices, the safety factor is difficult to circumvent any other way.

For wearables marketed to children, animals and seniors, easy access to small poisonous batteries is a major concern. According to Medscape.com, the increase in childrens lithium battery ingestion has jumped from 9 percent of all battery ingestions from 1985 to 2009 to 24 percent in 2008. The article cites a study from the journal Pediatrics, which notes that from 2000 to 2009, 92 percent of disk batteries from fatal ingestions or those with major outcomes were 20-mm lithium cells. Meanwhile, Poison.org warns that batteries lodged in the esophagus can cause serious burns within two hours of ingestion. The dangers associated with swallowed toxic batteries are compounded by the fact that children, animals and the elderly are often incapable of communicating the cause of their problem.

Rechargeable Lithium-Ion Microbatteries

One reason that the incidence of lithium-ion poisoning is on the rise is, in order to address the battery waste problem while accounting for the energy needs of todays advanced technological devices, designers have few options. Lithium-ion is one of only two rechargeable chemistries capable of delivering high energy density in a small size. On the micro scale, lithium-ion batteries excel at supplying the energy required to keep power-hungry devices running for a reasonable duration.

Because of its incredible energy density, rechargeable lithium-ion batteries are the long-standing favorite for todays most prevalent portable devices, and advancements in lithium-ion tech have opened the door for rechargeable options that provide long-lasting power at the miniature scale. But, in addition to ingestion hazards, the recent spate of battery fires indicates this chemistry has more than one serious downfall. From hover boards to cell phones to laptops and more recently, wireless earbuds, lithium-ion battery fires are regular fodder for tech news headlines. Add to this the form factor issues that come with this chemistrys battery design constraints, which do not allow for standard microbattery sizing and shapes, and the need for sealed-in batteries seems an unavoidable problem of the modern world.

Rechargeable Silver-Zinc Microbatteries

However, there is an alternative battery chemistry available today that provides the necessary power without the hazards associated with lithium-ion batteries. This is rechargeable silver-zinc.

Battery Safety

On the microbattery scale, the energy density of silver-zinc batteries is greater than any other chemistry currently on the market. The chemical components of these batteries, water, silver and zinc, are stable, non-flammable and non-toxic. This means the consumer can safely handle them, and, in the event of accidental ingestion, they present no toxicity or burn risk.

Product Longevity

Because there is no need to seal in silver-zinc batteries for safety reasons, the lifespan of a product can increase: just because the battery fails doesnt mean the entire device is rendered useless. Silver-zinc batteries dont require the additional safety components needed by lithium-ion batteries, and they can be made in traditional button/coin cell sizes. The result is a battery that, when used in a design that allows for removal, can be replaced at the end of its life or switched out for an alternative power source, such as zinc-air disposables.

Powerful, Long-Lasting Charge

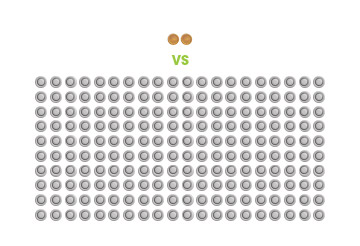

At microbattery size (up to 10 mm in diameter), silver-zinc cells have up to 88 percent more energy than their nickel-metal hydride disposable counterparts and up to 22 percent more energy than rechargeable lithium-ion cells in the smallest cell currently available on the commercial market. The high energy-density-to-size ratio makes silver-zinc batteries capable of supplying the charge duration necessary for running todays power-hungry wireless devices, including wearables, medical devices and wireless earphones.

Commercially Proven Technology

Commercially, rechargeable silver-zinc microbatteries are proving their merit in the medical device and hearing aid markets. In just two years, they have moved from a retrofit option for a few select hearing aids to be a built-in option in wireless hearing aid models from nearly every major manufacturer in the world.

The Future Lies in Rechargeable Removable – Recyclable Batteries

Recyclable batteries have the potential to reduce battery waste by the ton going forward, and this is an important step in the right direction. But to be truly sustainable, they also have to be easily removable at disassembly and, therefore, they must be safe for the consumer. With portable and wearable electronics becoming an ever more integrated part of life, full recyclability is also crucial. Even if you can easily get the batteries out of the device, if the components can only be downcycled, the result is still a degree of waste that, compounded over time, can be excessive. Because silver-zinc batteries are 100 percent recyclable, their use can help cut down on the constant need for sourcing virgin materials, which strains global resources and can result in unnecessary mining and mining byproducts that are environmentally damaging.

The Power Lies With the Battery Industry

The strides we have made in developing environmentally friendly chemistries that are rechargeable and safe are a huge move in the right direction. It is now time for implementation and improvement. With new chemistries continually under development, it is an exciting time to be working in the field of battery design. Reduce, reuse, recycle has been the mantra of the sustainability movement for good reason. Adhering to these three precepts helps fight climate change and protects our natural habitats from excessive trash and contamination, ensuring there are resources available for future generations. But more immediately, for the battery industry, these tenets are helping drive innovation in engineering and chemistry, which is to the benefit, health and well-being of us all.

For more information, visit ZPower.