Joshua Su, Sr. Engineering Manager • HZO

In recent years, lithium ion polymer cells in pouch format have found increasing use in portable consumer electronics. They are commonly being referred to as lithium polymer cells (hereafter referred as Li-Poly), although these cells are not of the true polymer types1,2. Compared to conventional batteries such as nickel cadmium systems, Li-Poly cell designs provide the highest specific energy (>220 Wh/kg) and energy density (>450 Wh/L) of all commercially available designs3. From a safety and fire protection standpoint, a high energy density coupled with a flammable organic, rather than aqueous, electrolyte has created a number of new challenges with regard to the design, storage and handling of batteries containing lithium ion cells. In order to maximize lifecycle and increase safety, lithium ion cells require the use of a Protection Circuit Model (PCM) when assembled together to form a battery. The PCM will generally provide the battery with overcharge/discharge protection, short circuit protection, current limitation, and voltage and current balancing in each cell. All of these factors are important in obtaining the maximum output and lifetime from a rechargeable lithium battery.

Consumer electronic devices have become increasingly more important for accomplishing everyday tasks. Moreover, people who rely on electronic devices tend to carry them along to locations in which the electronic devices can incur damage. One form of damage that can be particularly detrimental to an electronic device is water damage. Water tests conducted in the HZO laboratories show a common failure mode of shorting or corrosion at Li-ion batteries. Failure analysis finds the watertight cells of Li-Poly batteries to be robust, but the imbedded PCMs are vulnerable to shorts and/or corrosion, despite commonly being covered by protective tapes.

HZO has developed a CVD process to generate a thin film nanocoating that protects electronic devices and components from damage caused by water, other corrosive liquids, humidity, sweat, dust and debris. The CVD process involves placing the devices in a closed deposition chamber, vacuuming them as high as 10 mTorr, and then introducing vaporized coating gas. The typical cycle time is five to seven hours. To make a Li-Poly battery powered device waterproof using HZO technology, the battery also needs to go through this process. One big concern: can the Li-Poly pouch cell withstand this process?

Extensive studies have been carried out to obtain baseline data on the Li-Poly battery safety and performance under different discharge rates, temperatures and pressure conditions by NASA-JSC2,4,5. The NASA studies showed swelling of the pouch under extended low pressure conditions, as well as a loss of capacity. But if the pouch was constrained (not allowed to swell), cells showed no change in charge/discharge performance under vacuum conditions. There is no report on the cell leakage or venting when under vacuum conditions. The most rigorous vacuuming test condition reported was 0.1 psi (~ 5 Torr) for six hours.

As mentioned, the vacuum of HZO CVD process can be as high as 10 mTorr, 500 times stronger than NASA’s tests. To assess the Li-Poly pouch cell performance under this vacuum condition and/or with the thin film nanocoating, a set of experiments was carried out and the results of such studies are discussed here.

Test Plans for Assessment of Pouch Cells

A pool of new 1,500 mAh Li-Poly pouch cell batteries provided by an HZO partner, which is one of major battery manufacturers in China, were tested under different conditions. The tests carried out on the cells included: 1) pouch cell leakage test; 2) capacity test; 3) environmental test; and 4) life cycle test.

Pouch Cell Leakage Test

Besides the visual inspection of any electrolyte leakage, venting, explosion or fire on the tested cells, the most common industrial testing is to measure the impedance for a cell pouch. The impedance measurement was performed on a fully charged cell before the vacuuming experiments. A Fluke 115 digital multimeter was used for measurements. At a range of 40 MΩ, its resolution is 0.01 MΩ and its accuracy is 5 percent. The pouch cells were then placed in an HZO 5000 deposition chamber that was reduced from atmosphere to ~ 15 mTorr (±5 mTorr) within 30 minutes. The chamber temperature was room temperature and the vacuuming duration for this experiment was designed at 7, 15, 24 and 35 hours, respectively. The impedance was measured again immediately after the cells were removed from the deposition chamber.

Capacity and Cycling Performance Tests

The capacity measurements were carried out at room temperature with a programmable Neware BTS 5V3A battery testing system. The cycling performance test follows the following protocols. The pouch cells were first charged at a current of 750 mA (C/2) to 4.20 V/cell and allowed to saturate to 0.05C (75mA) as part of the full charge procedure. The batteries were then discharged at 750 mA to 3.0 V/cell, and the cycle was repeated. The cycling test was terminated by the program once 300 cycles were achieved.

Environmental Test

The environmental tests were performed in an industrial environmental chamber with temperature set at 60oC (±2oC) and humidity set at 90 to 95 percent. A total 10 coated batteries were visually inspected and fully charged before testing. The weights of the batteries were measured before and after 15 days environmental testing by using a Sartorius CPA225D balance with a resolution of 0.01 mg. Inspection of any electrolyte leakage, venting, explosion or fire was also performed on the tested batteries.

Results

Cell Leakage Test

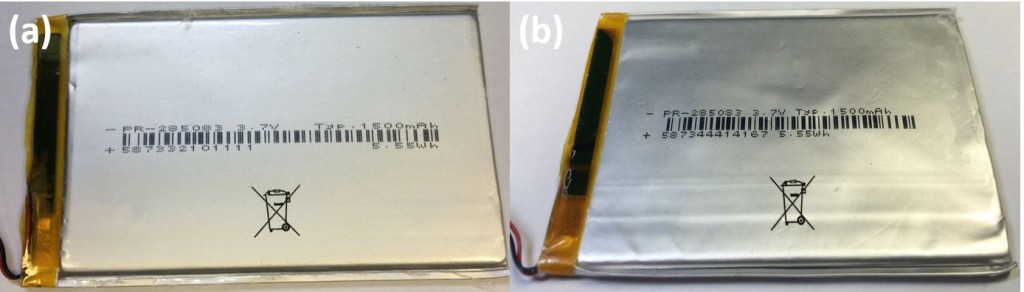

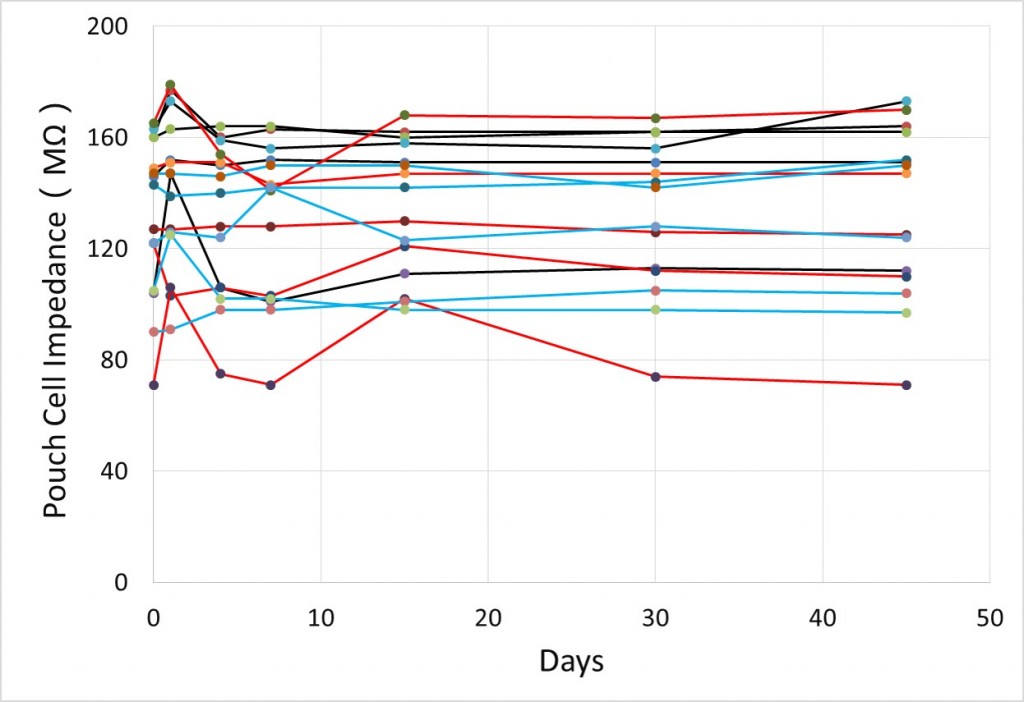

Fifteen pouch cells were prepared under a vacuum in groups of five for 7, 15 and 24 hours, respectively. The impedance was measured on the 15 fully charged cells before the vacuum test as described in the Test Plans Section. The cell impedance was then monitored for 45 days following the test. Although the cells showed swelling (Fig. 1(a)) during vacuuming and sometimes wrinkles on the aluminum foil (Fig. 1(b)) after the vacuum test, they did not exhibit any surface damage, venting or electrolyte leakage. Fig. 2 shows the time dependence of the cell impedance. All the cells, except one from 15-hours group, showed some degree of fluctuation at the first 15 days and no noticeable changes after that. Note that all the tested cells show impedance values greater than 20 MΩ, which is the spec set by the cell manufacturer. There is no statistically significantly difference in the variation of the impedance values between the three groups, indicating that even the vacuuming duration of 24 hours doesn’t affect the cell impedance.

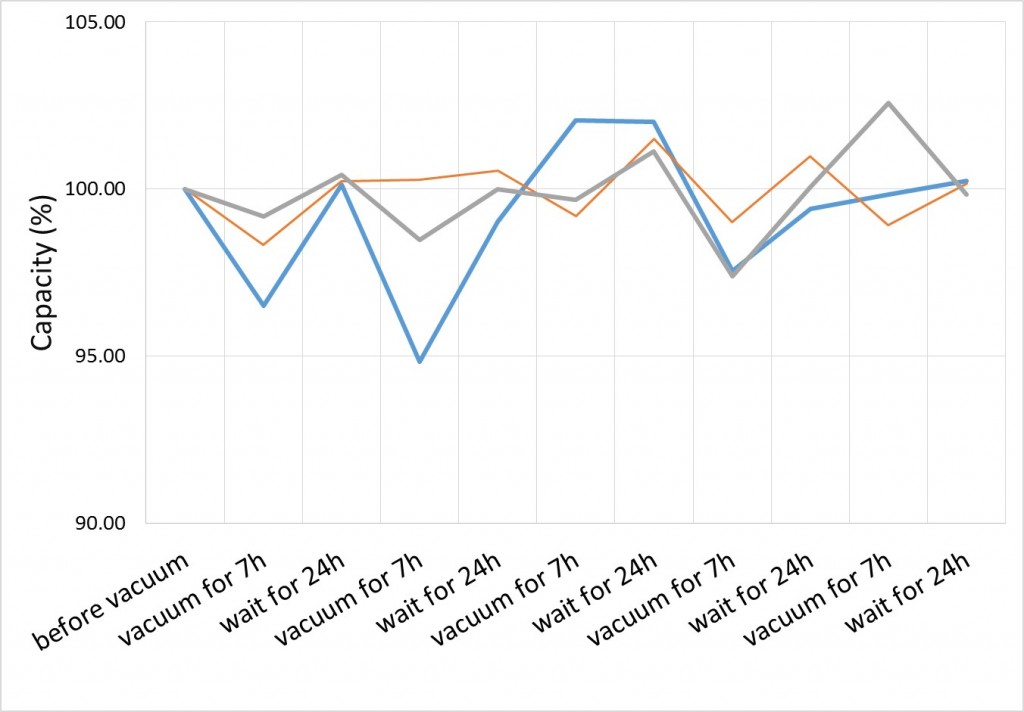

Figure 3 shows the capacity changes for three batteries subjected to various vacuuming events. The capacity was checked before and after seven hours vacuuming, followed by a 24 hours wait at room temperature. The process was repeated five times, thus a total vacuum duration is 35 hours. Although a capacity change up to 5 percent was observed, all three tested batteries had a capacity value close to 100 percent after the test.

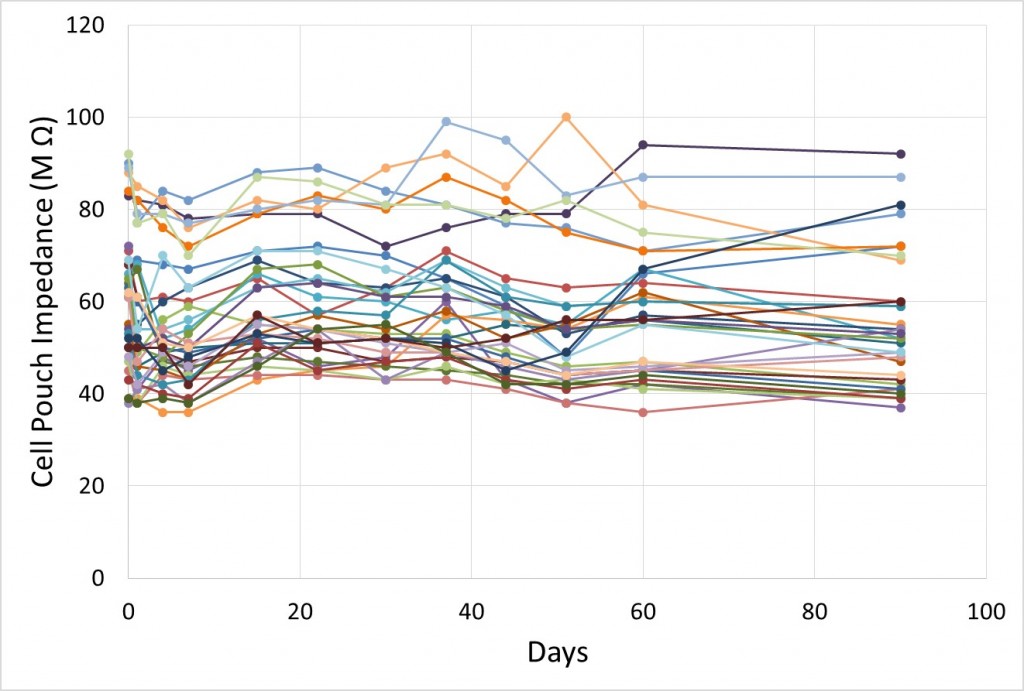

The previous two tests show that vacuuming alone does not impact the cell pouch impedance and battery capacity. The next experiment was to test the cells that were processed by a complete HZO coating cycle. A sample size was chosen to meet the statistical requirement of 80 percent confidence level and 95 percent yield rate (n=33). All 33 cells were fully charged and measured for impedance before the coating process. Cells, processed in three sets of 11, were placed in the deposition chamber with a cycle time of seven hours. The cell impedance was monitored for 90 days after the test. Figure 4 shows the time dependence of the cell impedance. There is some degree of fluctuation in the impedance value during the 90 day test period, but no samples showed a loss of impedance. Also note that all the tested cells showed impedance values greater than the manufacturer specified 20 MΩ. The test result did not show any pouch leakage or damage during vacuuming process or the 90 day test period.

Environmental Test

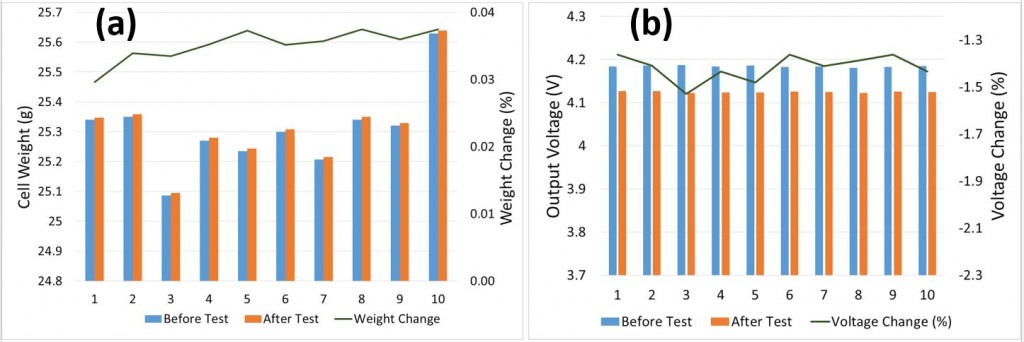

Ten cells were fully charged, coated, and weighed by a Sartorius CPA225D balance. They were placed in an environmental chamber (60oC and 90 to 95 percent RH) for 15 days. Water condensation on the cells was removed by using a soft, lint-free cloth after the test. The visual inspection showed no cell swelling and/or deformation, venting, electrolyte leakage, or fire. Figure 5(a) shows the weight changes on the cells before and after the test. A weight gain of 0.03 percent to 0.04 percent was observed, which is far below the manufacturer cell spec requiring the weight change not greater than 0.1 percent. The voltage changes of the cells are presented in Figure 5(b), showing a maximum voltage drop of 1.5 percent. The test results pass the test spec set by the cell manufacturer.

Life Cycle Test

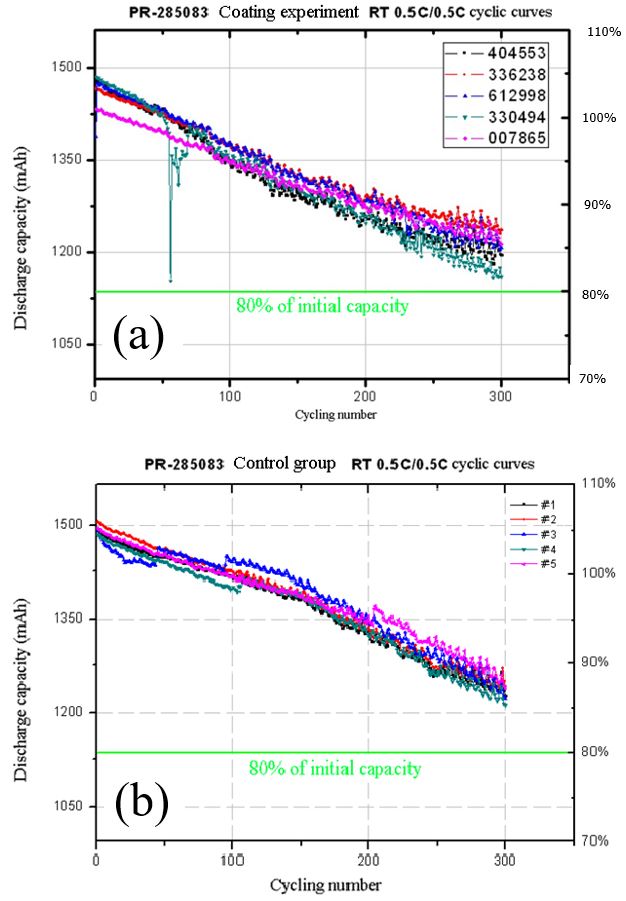

Five cells were fully charged, coated and cycled in a Neware BTS 5V3A battery testing system. The charge/discharge rate was set at 0.5 C and the cycle number targeted at 300 cycles. Figure 6 illustrates the discharge capacity as a function of cycling number on five coated (a) and five control (b) batteries, respectively. The coated batteries showed similar capacity drop trend as the controls. Although the average capacity of coated cells is slightly lower than the controls, all five coated cells had discharge capacity greater than 80 percent after 300 cycles, which passes the spec set by the cell manufacturer.

Conclusions

The 1,500mAh Li-Poly cells were tested under various conditions mimicking and exceeding those used during HZO coating processes. The pouch cells did not exhibit any hazardous results of deformation, electrolyte leakage, venting or fire at the vacuum and environmental tests. Although the cell impedance showed some degree of fluctuation after the vacuum test, which was up to 24 hours, none of the test cells exhibited degradation during the post-vacuuming test period (up to 90 days). The cells showed excellent performance even after a total 35 hour vacuuming with no more than a 5 percent drop in capacity and a trend towards recovery. After 300 charge/discharge cycles, the vacuumed and coated cells provided a capacity greater than 80 percent of the specified value. The test results indicate the pouch cells have a good tolerance to vacuum exposure.

Acknowledgements

We would like to express our gratitude to Kai Yang and Marcellus for setting up the battery testing systems and performing the battery tests. A special thank is given to Like Xie for their continuous supports and consultation. We would also like to thank our partner for providing the cell and battery samples for testing.

References:

- Wikipedia, http://en.wikipedia.org/wiki/Lithium_polymer_battery.

- J. Jeevarajan, “Characterization of Commercial Li-ion Cells in Pouch Format”, the 2014 Space Power Workshop, April 2014.

- V. Etacheri, R. Marom, R. Elazari, G. Salitra, and D. Aurbach, “Challenges in the development of advanced Li-ion batteries: a review”, Energy & Environmental Science, issue 9, 2011.

- J. Jeevarajan, “Safety and Long-Term Performance of Lithium-ion Pouch Cells”, the 222nd Electrochemical Society Meeting, Houston, TX, Oct. 2012.

- NASA report, NASA Aerospace Flight Battery Program, NASA/TM-2010-216727/Vol. I, 2010